Core R & D

Core R & DOur company preliminarily realizes informatization in the design, manufacturing, management and service using such technological means as three-dimensional CAD, CAM, CAE, PDM, CAPP and ERP, and has passed the review of National Ministry of Science and Technology and been awarded the demonstration enterprise of national CAD application engineering.

Our company has been recognized as a national enterprise technology center as well as a provincial high-tech enterprise by national and provincial technology authorities respectively.

Design platform

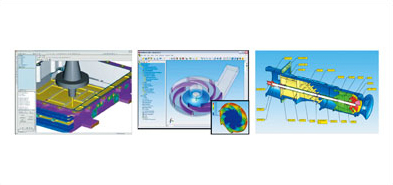

Design platformOur company has established a unified three-dimensional CAD platform, all the design and process technical staffs use three-dimension design, andthe process of all products from casting and machining to assembly and testing iscalculated, analyzed, simulated and demonstrated in the computer.

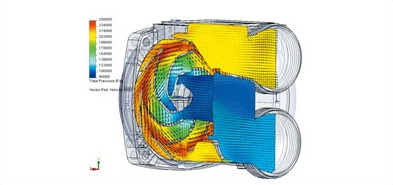

Performance simulation analysis platform

Performance simulation analysis platformCFD (computational fluid dynamics) is used to analyze and calculate the flow field (such as velocity field and pressure field) inside the pump and then predict the performance parameters to optimize the design.

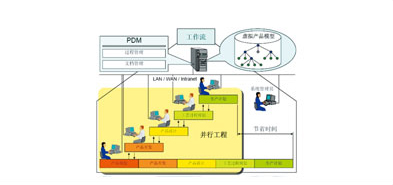

PDM rapid design system

PDM rapid design systemPDM design library deeply integrated with CAD ensures the standardization and normalizationof the design, and improves the design efficiency and market response speed.

CAM numerical control system

CAM numerical control systemWe have a five-axis three-linkage machining center, with more than 20 sets of CNC equipment, and apply internationally famous UG numerical control machining programming software to the machining programming of turning of shafts and sleeves, milling of irregular parts and other processes. This plays a very important role in machining the blades and guide blades of large diagonal flow pumps and tubular pumps.